The Lasers and Materials Engineering Groups

Research and Development

Laser Imaging

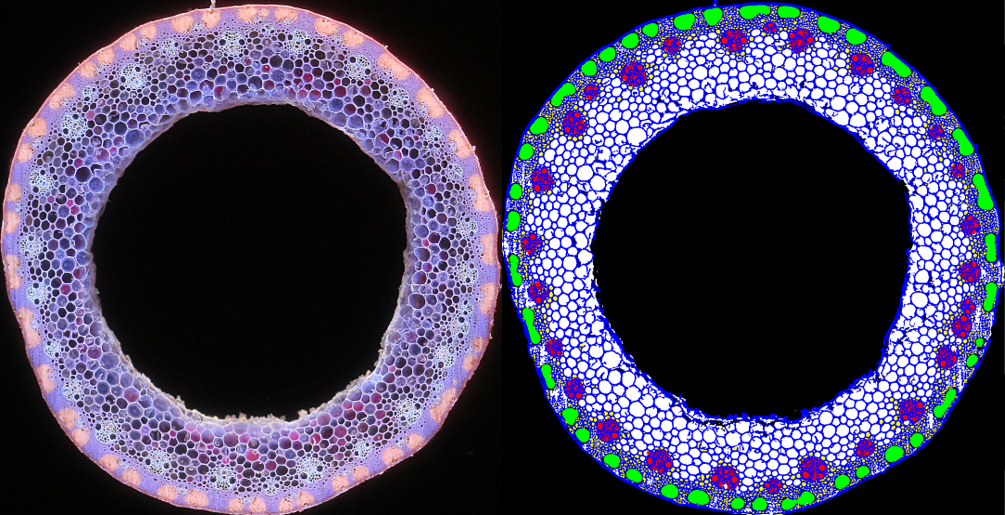

“A laser is a solution looking for a problem” – Theodore H. Maiman (inventor of the laser). The invention of the laser has revolutionized human technology, enabling many applications that include laser printers, barcode scanners, DNA sequencing instruments, fiber-optics, and laser surgery to name a few. Our lab offers a brand new microscopy technique called Laser Ablation Tomography (LATscan). LATscan uses an ultraviolet (UV) pulsed laser to continually ablate thin layers of samples while simultaneously imaging them.

These images perfectly capture the cross-sections in their natural state prior to ablation. The color resulting from UV-induced fluorescence in the images allows for easy image segmentation to identify microscale anatomical and compositional features. The sections can also be illuminated with other light sources. The images are then stacked to produce 3D models for volumetric microanalysis. The image resolution of the sections is comparable to optical microscopy modalities, and the distance between slices is only limited by the resolution of the stage feeding the sample into the laser ablation plane. Besides imaging and 3D reconstruction, our lab is also developing machine learning and image processing techniques have been developed for segmentation, classification and quantification of features.

Advanced Materials

Our group also oversees the Composites Engineering Research Laboratory (CERL). CERL supports industry in composites manufacturing, process development and optimization, advanced materials analytical services (including non-destructive testing techniques), focused educational training, and prototyping. At CERL and USM, our group is developing novel bio-inspired materials, taking inspiration from solutions that have been created by evolutionary design. Through modeling, prototyping and experimentation, we are interested in smart composite structures, like the heliocoidal stacked laminate composites inspired from the mantis shrimp.

We also conduct basic materials science work with developing structure-property-function relationships for shape memory alloys (SMAs). SMAs are amazing materials that react to heat heat, magnetic fields, loads and impacts, having the ability to “remember” their shape (large deformations recovered via heating, called the Shape Memory Effect) and behave like super-springs (large deformations recovered by the removal of load, called Superelasticitiy). By studying the compositions, heat treatments, microstructures, and functional behavior, we hope to gain a better understanding of these materials so that they can be better applied in practical applications.

Engineering Applications

Creating modalities and devices that enable new and/or improved functionality is at the heart of all engineering. We are designing and prototyping low-cost prosthetic arm for underprivileged people. We are also using shape memory alloy (SMAs) to develop low-cost high-fidelity robots that can be used by surgeons. Our group is also interested in deployable mechanisms in satellites that can ultimately be used for better communication and/or higher power generation.

We also collaborate with doctors from Maine Medical Center to develop medical devices. One device is a mock ventricle assist device (VAD) that will help train the users of real devices and get them comfortable with life with a VAD. Another device is a surgical wound closure device that reduces the number of internal wound closure surgery-based trips a patient needs to make to the hospital.